Fiber Cement Board

Model No.︰1.2*2.4

Brand Name︰krs

Country of Origin︰China

Unit Price︰US $ 15 / pc

Minimum Order︰100 pc

Product Description

Fiber Cement Board

KRS fiber cement board are man-made from a matrix of cement and cellulose re-inforced with fibres and fillers. The ratio of each ingredient can be varied to ensure that the finished product is able to meet the performance requirements demanded by each application. A wood grain is imprinted onto the surface during the manufacturing process.

Fiber Cement Board are available in many forms, shapes colours and textures. There is something to suit almost any project requirement or budget with an associated variation in cost dependent on quality of the material used. There are many types of material used to clad a building which range from the common house brick or tiles through to wood boarding with much in-between. In recent times there has been a marked increase in the desire to use fibre cement as an exterior cladding material. The use of large format cladding panels for external cladding was pioneered both in North America, Europe and Africa.

KRS fiber cement board offers a wood-like appearance with greater durability than most other siding products. It will not rot, buckle or warp and can hold paint for several years longer than conventional wood siding.

Fiber Cement Board Advantages

ü Durable & Long Lasting

Fiber cement siding is impact resistant, not affected by moisture (when painted/properly installed) and can last for decades. It won't shift like vinyl can with temperature swings and won't rattle like vinyl in strong winds.

ü No Rot Nor Succumb To Pests

If you've ever had old hardboard siding, you'll know what "rot" is all about. Fiber cement cladding isn't affected by moisture so it won't rot, particularly on those shady, northern-exposure sides of the house down near the foundation. You don't have to worry about termites or similar pests that threaten wood siding either because fiber cement isn't affected by these insects.

ü Design Versatility:Fiber cement products are available in a variety of textures, profiles, and colors matching your design requirements. One option is horizontal lap siding, which includes profiles such as Dutch, beaded, and traditional. Shaped fiber cement siding is available as shingles, half rounds, octagons, and random squares (with either a straight or staggered edge). Vertical siding options include a traditional stucco appearance, smooth, or cedar (either without vertical grooves or with regular interval grooves.) Fiber cement soffits are also available in smooth and cedar textures, both of which can be vented. Matching low maintenance composite trim materials can complete the architectural design.

ü Dimensional Tolerances and Stability

This kind of siding doesn't expand and contract much with changes in the environment which makes it a good base for paint. When the paint adheres longer, you won't have to paint your house as frequently which equates to a lower overall home maintenance cost.

ü Fireproof

Fiber cement is fireproof and carries a Class 1(A) fire/flame spread rating. Class 1 products have the highest level of fire protection whereas class 10 products have the lowest or no level of fire protection. That's a nice thing to have particularly in areas prone to wild fires, brush fires with wind-driven embers.

ü Available Primed and Painted

Fiber cement siding manufacturers offer their products both primed and primed-and-painted. The paint that's applied at the factory is done so under optimal conditions and is likely to last longer than conventional paint applied after the siding is installed.

ü Long Duration Warranty

Fiber cement siding holds paint well, with some products warrantied to hold paint for up to twenty-five years, though on average 7 to 15 years can be expected. Transferable product warranties can last as long as fifty years.

ü Good Aesthetic Appeal

The various fiber cement cladding products (boards, shakes and panels) do an effective job at presenting the look of a home sided with wood yet without the inherent drawbacks of wood.

Payment Terms︰ TT

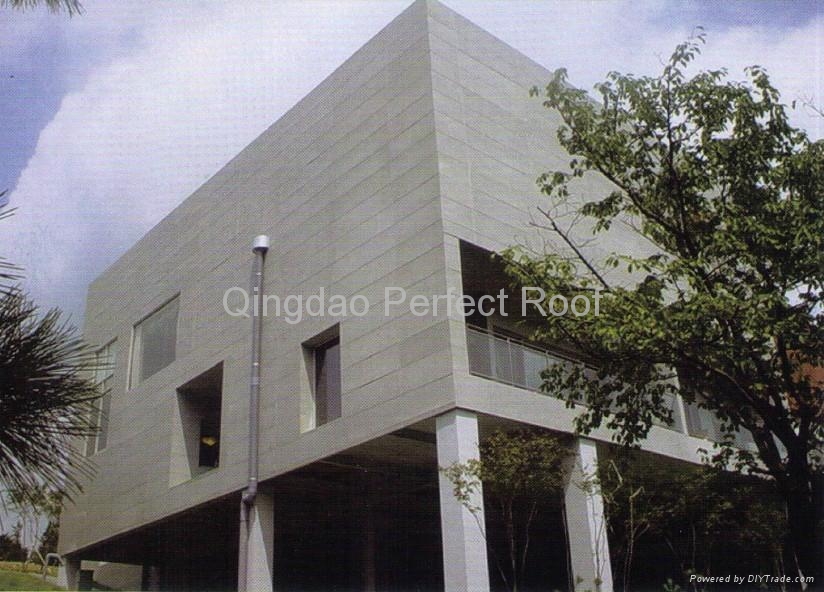

Product Image